Description of equipment

|

| INVERTEC STT II |

How is the STT II source working?

The unique control of entire welding cycle is in the

scanning of voltage parameters on the arc and evaluation

of measured values, so that the source instantaneously

reacts on all phases of the spray metal transfer to the

weld pool according to real situation on the arc. The

source is working with direct feedback of the welding

parameters control. In principle the STT source can be

described in the following way: when welding in the

short-circuitting area, changing of the short-circuitting

phase and burning phase on the arc occur. The source is

capable, through its unique scanning of the parameters on

the arc, to recognize the coming of the individual phases

and in the real time will adjust the welding parameters.

At the beginning of the short-circuitting phase the STT

source will limit the welding current for 10 A.

At the beginning of the phase of arc restriking the

source will limit the welding current for cca 50A.

Control of the welding current is independent on the

operator and is proceeding automatically.

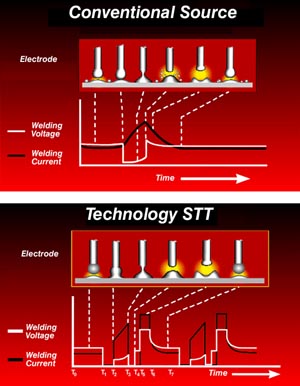

In fig. 1, there is seen characteristic flow of voltage

and welding current with the standard source with flat

characteristics ( source with constant voltage – CV)

and the source STT II in relation to one cycle of the

weld metal transfer to weld pool.

|

| Fig. 1 |

Advantages and possibilities of STT II source

The above stated principle of STT II activity is given by a set of circuits, which control entire process and control, for example, the circuit of easy welding, which continuously compares real values on arc with the reference values stored in memory and with the values of preceeding cycles evaluates situation and in the real time performs proper interference into welding parameters. Then , there is here a unique circuit called „dV/dt detector“, which identifies the phase closely before the ending of short-circuit.

STT source is a welding source GMAW (MIG/MAG), which works neither with constant current characteristics, CC nor with constant voltage characteristics CV. It is a source with a wide range of welding parameters control, where wire feed speed and welding current are controlled independently.

Welding parameters are being set according to the real need of all phases of welding cycle.

Advantages arising from the principle of STT source

- heat input in weld is minimal

- root deformation is thus decreased

- area influenced by heat is smaller

- minimal spatter up to 90% lower than with

conventional sources GMAW (MIG/MAG)

- weld cleaning is minimal

- area around weld is clean

- size of weld pool is the same in any position and

situation of welding, for example, at the end of

a thin sheet, in weld root, the weld pool is not

increasing

- operator need not be afraid of sagging

- even less experienced operator is capable

of welding weld roots,even in thin sheets

up to 0,6mm and in downward vertical

position!!!

- process is flexible

- STT source will also easily manage a wide

gap between materials to be welded, for

example sheets 3 mm, gap 12mm!!!

- STT source will also easily manage a wide

gap between materials to be welded, for

example sheets 3 mm, gap 12mm!!!

- perfectly controlled process

- when welding thin sheets, weld roots etc.

Replaces existing technology of welding

with non-consumable electrode GTAW (TIG),

with several times higher productivity

and better welding results

- when welding thin sheets, weld roots etc.

Replaces existing technology of welding

with non-consumable electrode GTAW (TIG),

with several times higher productivity

and better welding results

- for welding unalloyed and low-alloyed steels

- enables use of shielding by CO2 gas, at high quality of weld

- saves welding costs

- enables choice of larger wires

- saves costs for filling material

- saves costs for filling material

- weld appearance is excellent

- no grinding is needed!!!

- no grinding is needed!!!

- STT source is easy to use

- training of attendance is short

- user will use the advantages of STT

source „from the first day“

- harmful fumes are lowered to minimum

- environmental pollution is low

- environmental pollution is low

- enables welding of common unalloyed and

low-alloyed steels, high-alloyed steels

and electroplated steels- universal source for a wide spectrum of users

- enables application of technology of

soldering by electric arc, for example

thin sheets of car bodies - higher soldering speed with lower heating of parts being soldered

- various shielding gases can be used, including pure argon and helium for stainless steels

- user has a choice according his

possibilities and price

- application of hard-facing

- due to low heat input to weld pool, only minimal mixing with base material occurs and build-up weld has in many cases required properties already in 1st layer and does not suffer from breaks

|

|

|

| Fig. 2 - Traditional source (left) - Welding with STT II (right) | ||

Controls of STT source

Practical use of STT II

Technical specification of INVERTEC® STT® II

| Name | Code for order | Feeding (V) |

Output current and voltage | Input current at loading | Range of output currents | Weight (kg) |

Dimensions (mm) |

||

|---|---|---|---|---|---|---|---|---|---|

| 208 | 230 | 460 | |||||||

| Invertec STT II |

K1525-1 | 208/230/460 3 phase 60Hz |

225A/29V/60% | 33 | 30 | 19 | Top current 0-450A Bottom current 0-125A |

53 kg | 589x336x620 |

Assembly of STT source including feeder

|

| Feeder LN-742 |

Feeder LN-742, No. of order K617-1 can be provided with guide rolls for wire diameter from 0,6 to 1,2mm, for unalloyed welding wires, low-alloyed wires and high-alloyed wires. Feeder LN-742 is provided with a standard euro plug for connection of welding guns. The user has a choice according to his requirements.

Recommended equipment

Remote control for bottom and top current.

10-pin connector, cable 7,6m.

No. of order K942-1.